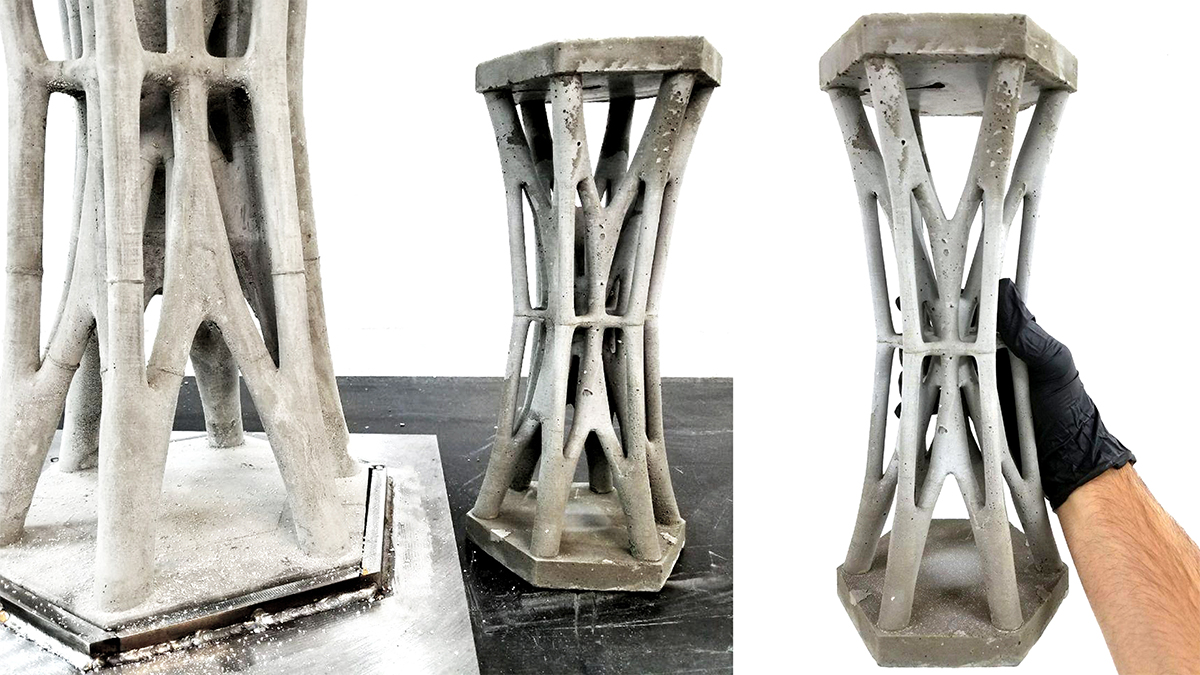

Cast In Place Funicular Specimen

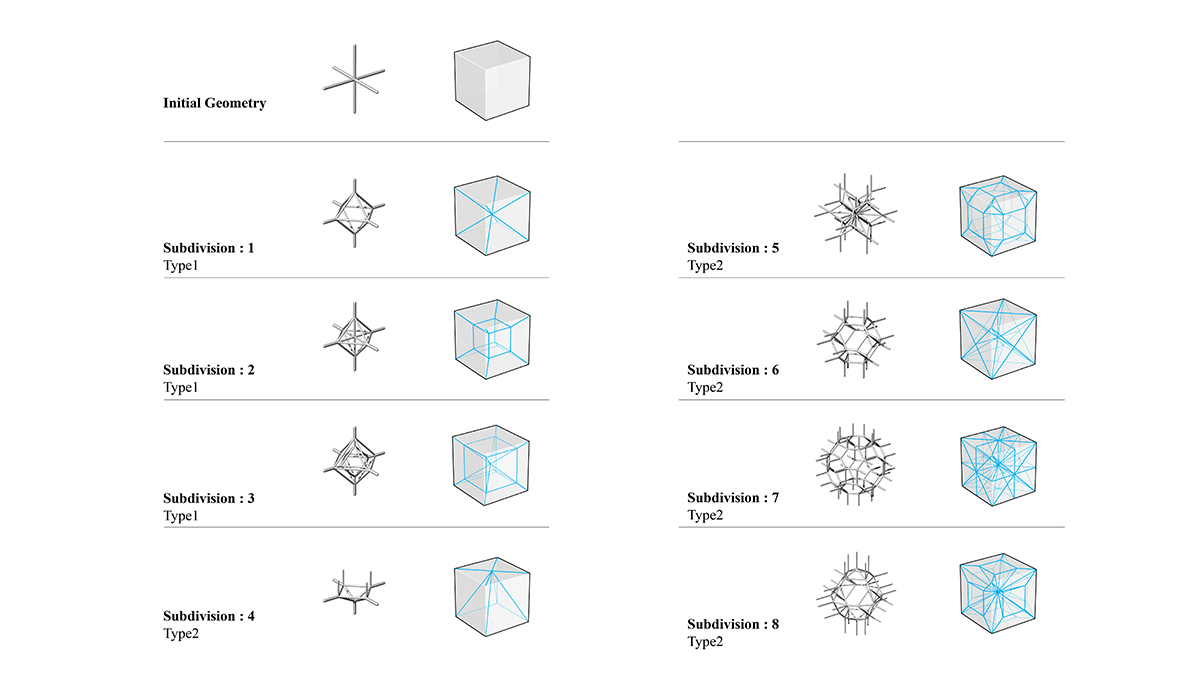

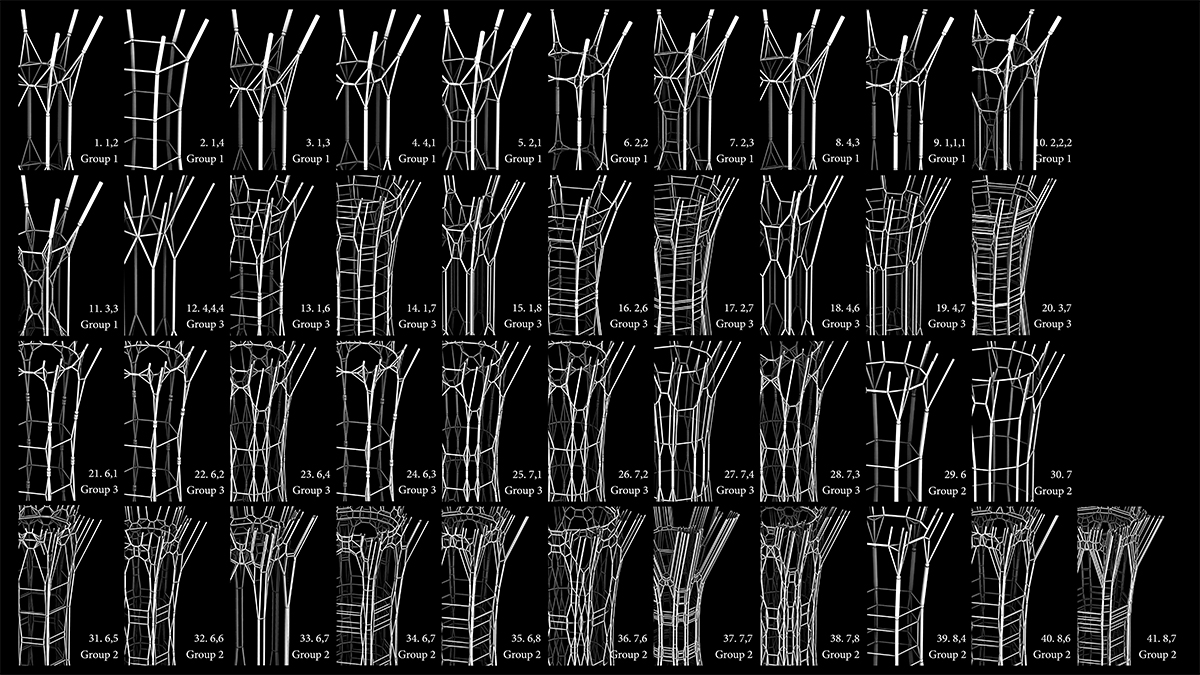

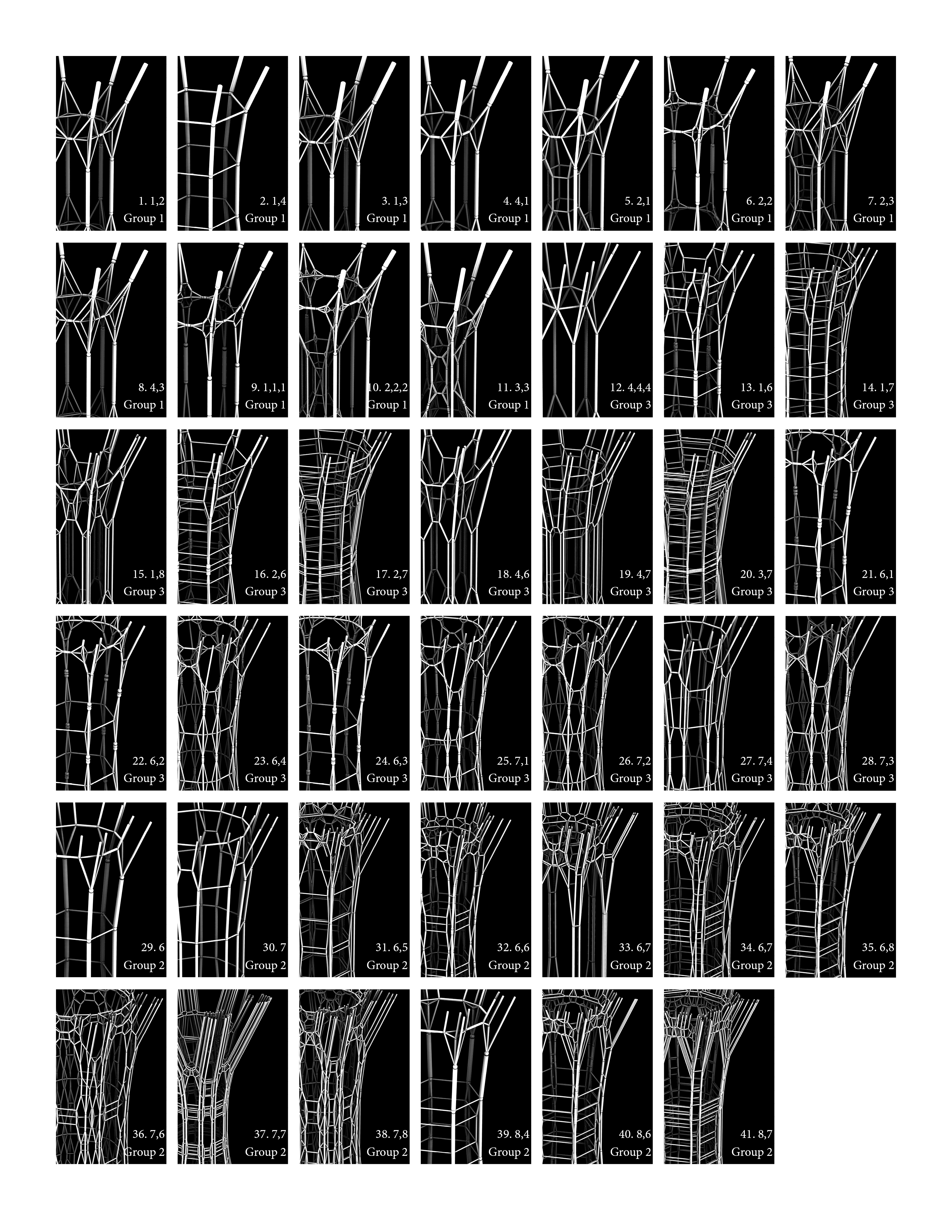

When we talk about unconventional and innovative structural forms, graphic statistics is always a great part of the conversation. It allows designers to iterate through countless ideas and have confidence that the result will perform to a good extend without the use of conventional mathematics. However, due to its geometric and “graphic” approach, materiality and physical behavior is not the center of its focus. This also leads to the question of constructability and predictability of the final built. This matter revealed itself to me and our team at PSL when I start designing the Saltatur. To address these questions we needed a series of small-scale specimens to fabricate and load test and compare the result with our structural simulations. I created a method that creates a series of funicular geometries with various densities and topologies. We tested those based on our fabrication constraints and find one that was feasible to build. Then we 3d printed and assembled a discrete thin mold and cast our specimen with a lightweight high-performance fiber reinforced concrete. The results of the load test are very exciting. It showed how efficient the structure was when everything exploded altogether at the yield point. You can read the details of this experiment and the two papers that came out of it on the PSL webpage.